HOW RAINSCREEN WORKS

Rainscreen cladding can be used on block, pre-cast concrete or on integral wall (timber or steel) constructions. Typically, insulation is placed on the outside of the structural wall. Best practice is to install an aluminium rail system on the structural wall, and it’s on this rails system that the actual panels are affixed.

The specification of the rails depends entirely on a combination of the features of the panels to be hung, and the location of the building.

WHY RAINSCREEN WORKS

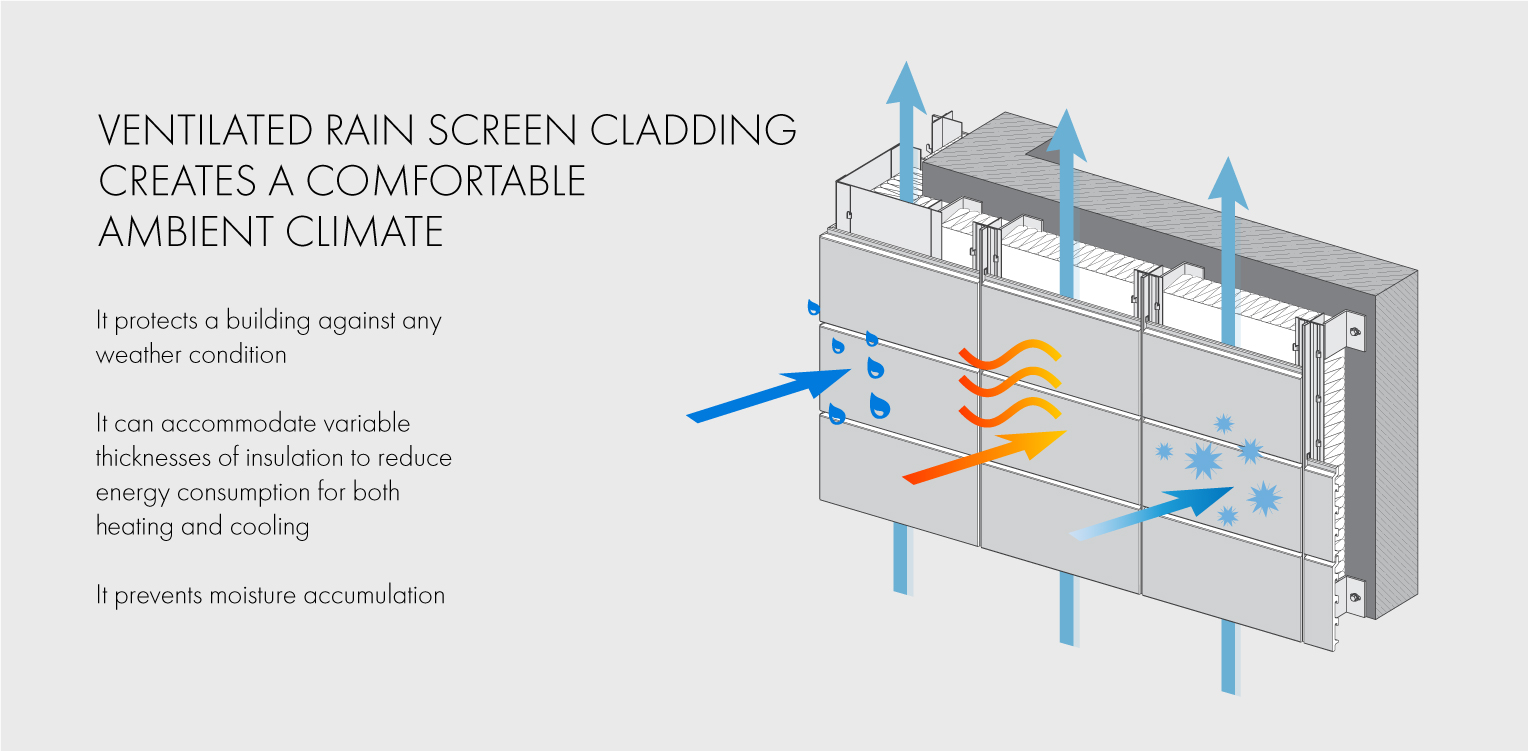

Animated illustration of a ventilated rainscreen cladding system showing airflow and moisture management.

Rainscreen provides a weather-resistant decorative finish to a building. Using a tried and trusted system of rails, air-gap, insulation and suspended panelling, Architects can control the inside environment of a building, whilst providing an aesthetic exterior finish.

All of our cladding systems are designed for ventilated cladding façades. Ventilated façades promote “Healthier Buildings”. This construction method allows for insulation (even 200mm+) to be placed on the exterior of a building thereby minimising thermal bridging. It also means that excessive heat & cold can be dissipated away through the ventilation gap between the panel and insulation materials which can reduce heating and cooling costs of a building.

The range of rails and cladding panels provided by Elemental, ensure that your building remains highly weather resistant and insulated. Our vast selection of panel types and finishes, mean that you can get just the bespoke look that was envisaged at the design stage.

All of our cladding panels and rail systems are suitable for both new and refurbishment applications. Many buildings can be given a facelift by installing an attractive light weight-façade over a tired façade.

Our cladding systems can be installed from “ground up” or “top down”.

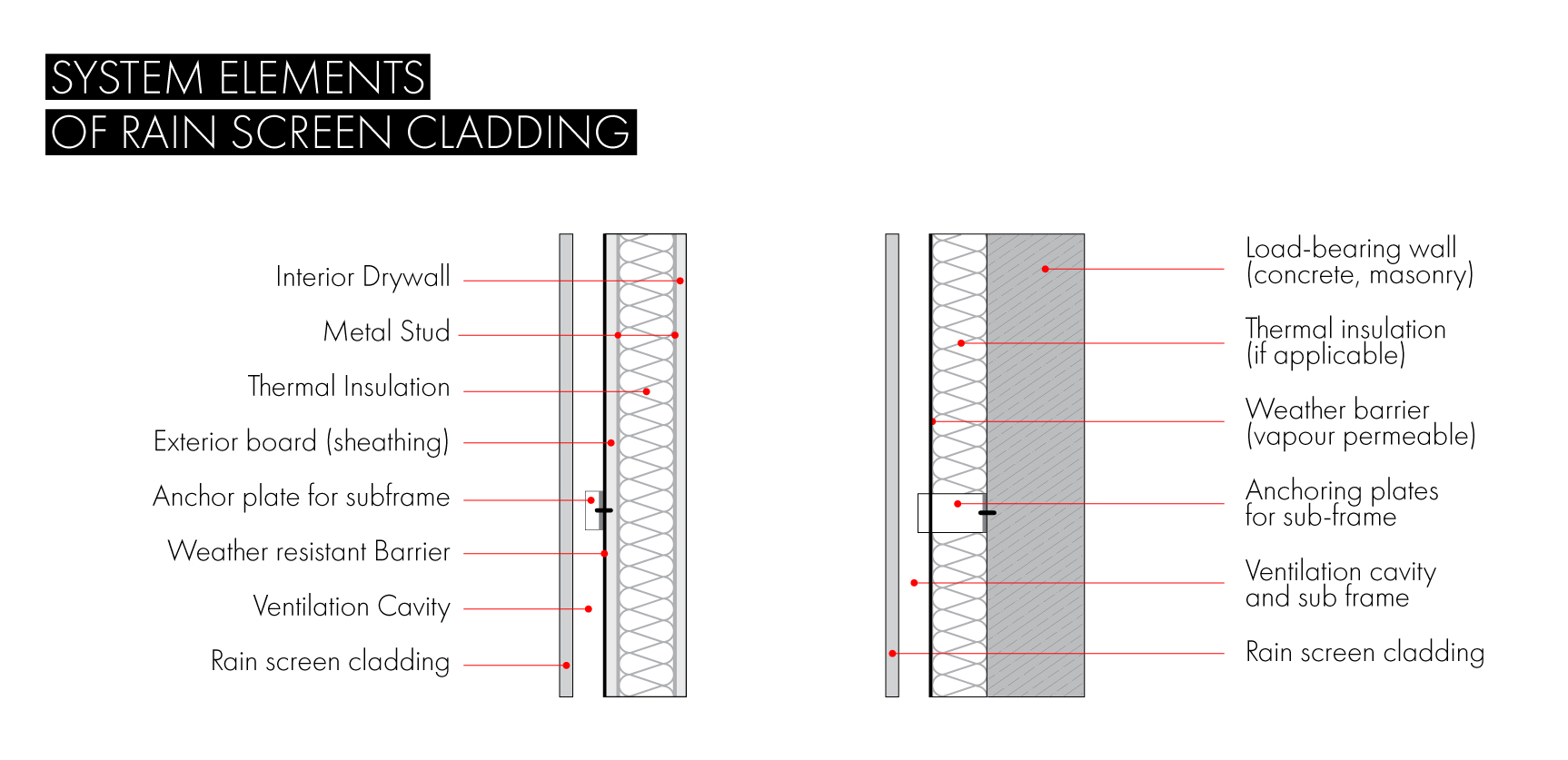

RAINSCREEN SYSTEM ELEMENTS

A ventilated rainscreen cladding system creates a breathable façade assembly by allowing controlled airflow behind the outer cladding panels.

The ventilated cavity between the insulation and outer panel helps manage moisture, improve thermal performance & protect the building.

These systems can be configured with various insulation thicknesses and panel materials to meet design and performance.

RAINSCREEN AESTHETICS

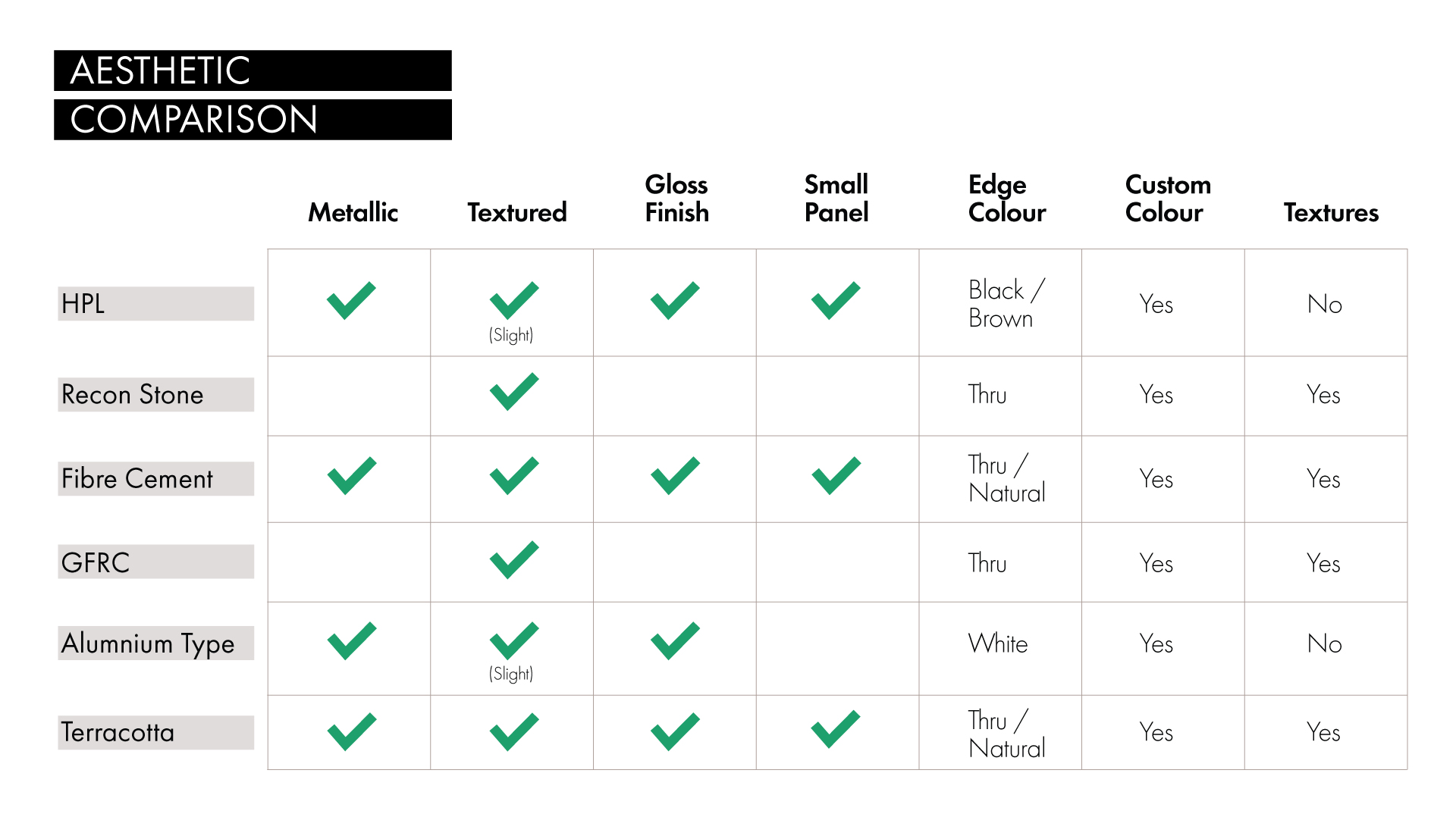

This table compares the aesthetic characteristics of key cladding panel materials offered by Elemental, including high-pressure laminates (HPL), recon stone, fibre cement, glass-fibre reinforced concrete (GFRC), aluminium types and terracotta.

It shows which materials are available with metallic or textured finishes, gloss surfaces, small panel options, edge colour selections, custom colour availability and texture options, helping architects and designers choose based on visual and design priorities.

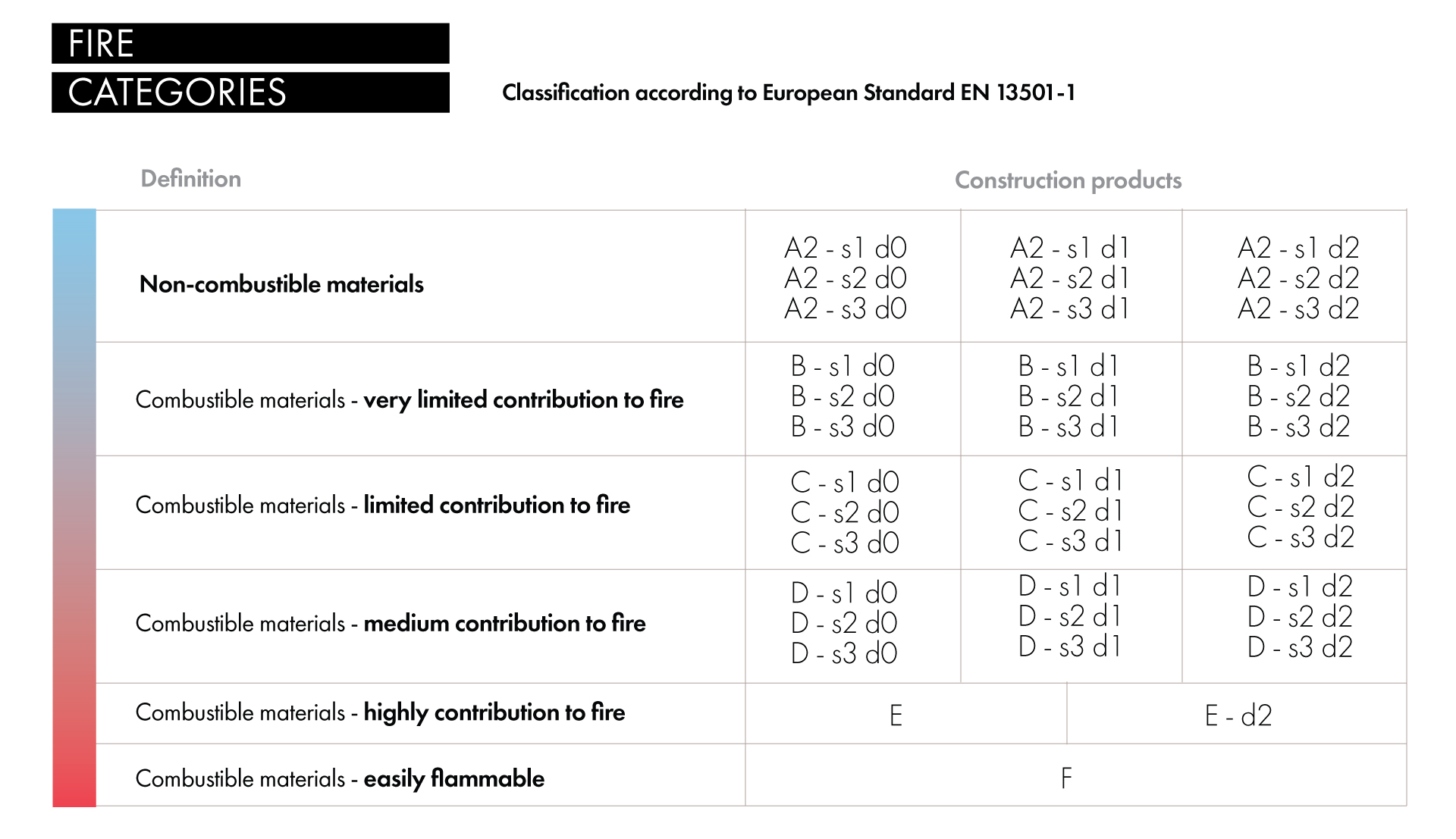

FIRE CATEGORISATION

This table compares the fire performance classifications, and design characteristics of various cladding panel materials provided by Elemental.

Materials shown include high-pressure laminates (HPL), recon stone, fibre cement, glass-fibre reinforced concrete (GFRC), aluminium panels and terracotta.

Materials support secret fix or face fix systems, their associated fire performance ratings, standard or custom design considerations to assist architects.

MATERIAL COMPARISON

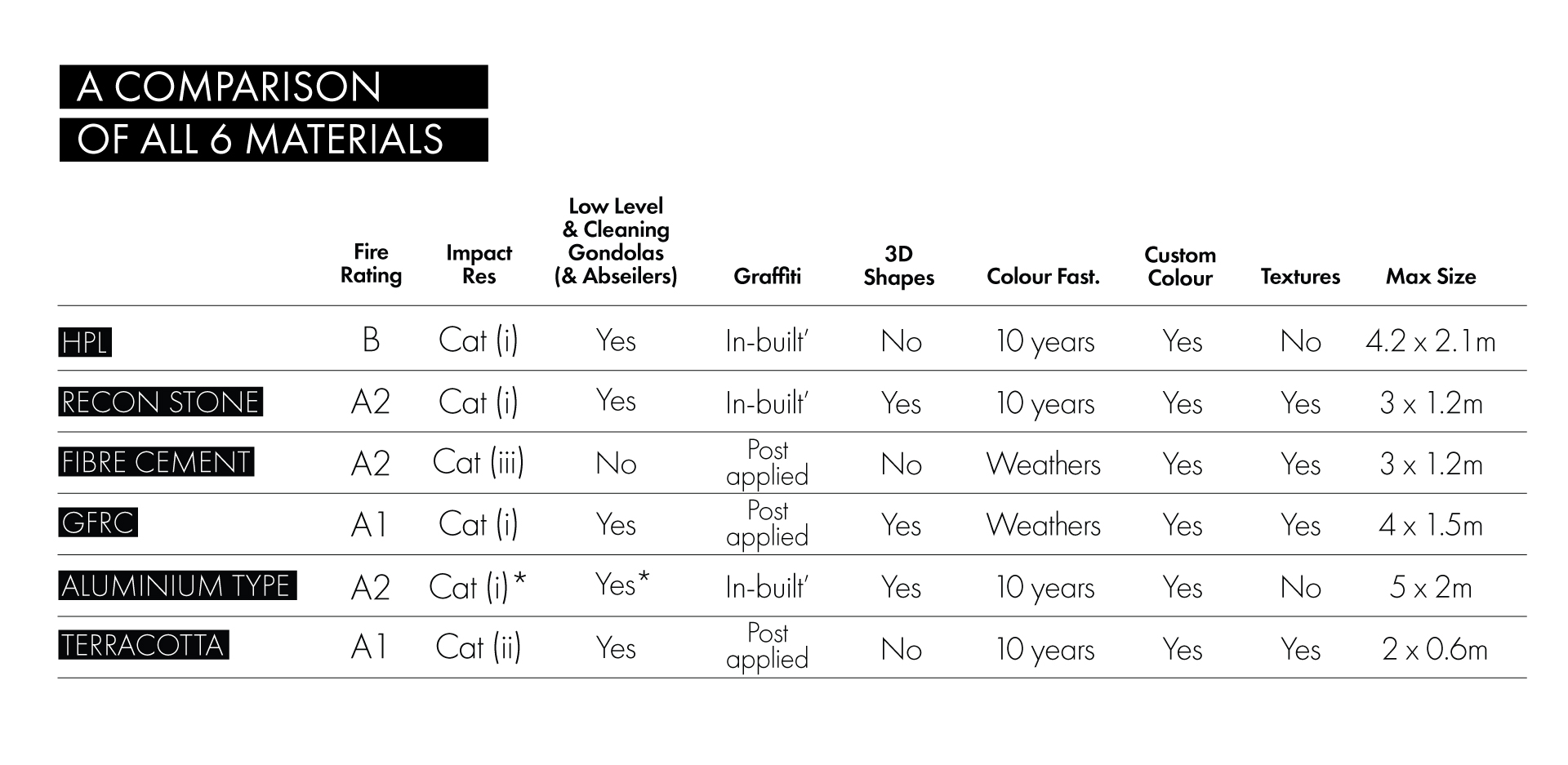

This table compares six cladding panel materials across a range of performance, durability and design-related criteria.

The comparison includes fire rating, impact resistance, suitability for low-level cleaning and gondola access, graffiti resistance, ability to form three-dimensional shapes, colour fastness, availability of custom colours, texture options and maximum panel size.

Call: +353 (0)1 293 8951

Email: info@elemental.ie

Subscribe

Get access to latest news and all the features by subcribing here.

Contact Address

#29, The Cubes Offices, Beacon South Quarter, Sandyford Dublin 18, D18 A264

Regular Trading Hours:

9 am until 5.30pm

Monday – Friday